Description

Explore our Basic Resin, which is perfect for general-purpose 3D printing and prototyping. It is ideal for creating simple models, functional parts, and prototypes due to its ease of use, affordability, and good surface finish.

Basic is a type of universal LCD light-curing resin with features such as low odor emission, rapid prototyping, high printing success rate, high precision, and high strength after printing while still retaining a certain toughness. It is applicable for LCD equipment in the 405nm band.

Basic is widely used in model production, culturally related, art design, mold verification, etc. It is especially suitable for studios and individual users.

Recommended Applications:

- Model Manufacturing

- Design verification

- Cultural periphery

Key Features:

- Colors diverse

- Easy to model.

- High precision

- Balanced strength and toughness

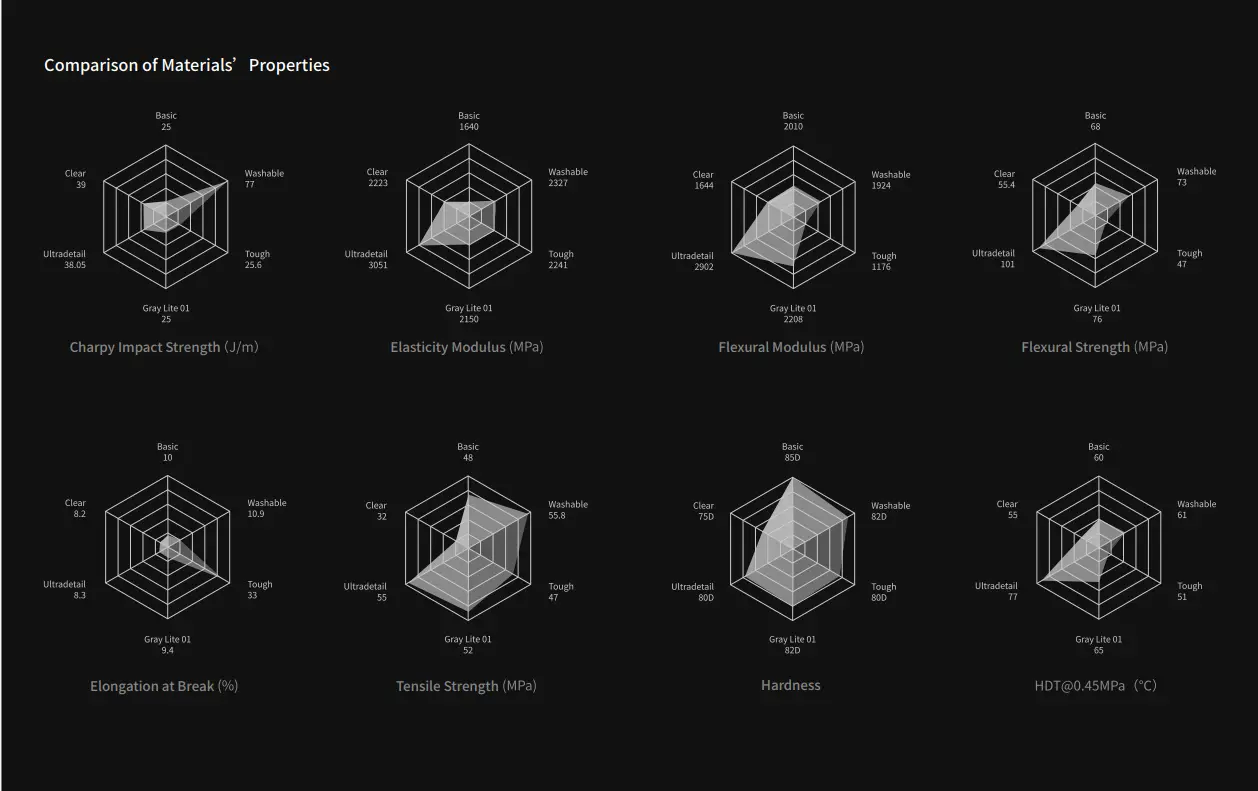

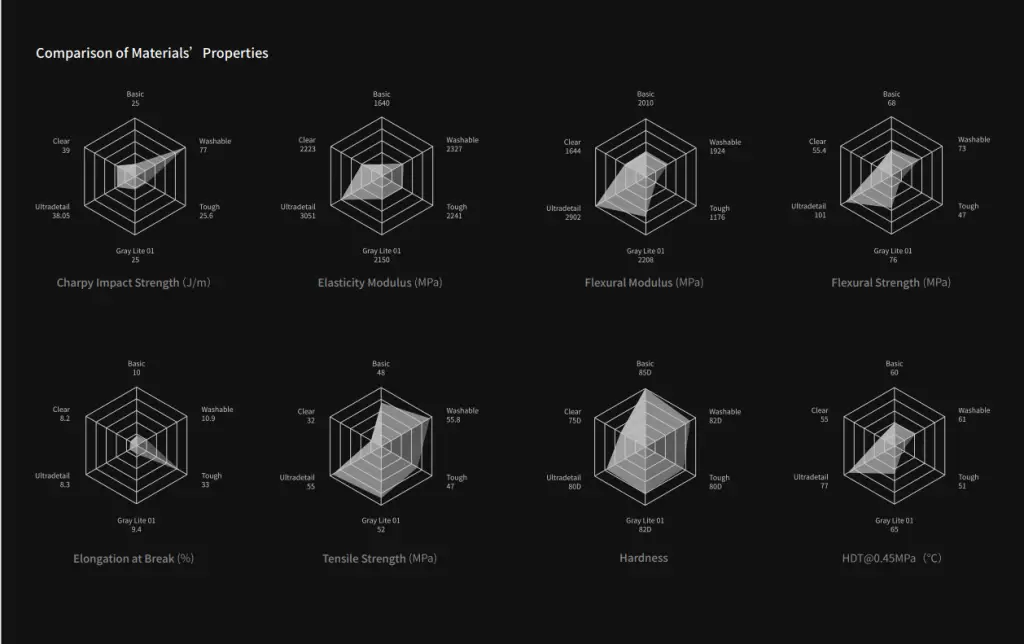

Technical Specifications:

- Tensile Strength: 48.0MPa

- Elongation at Break: 10.0%

- Flexural Modulus: 68MPa

- Hardness (Shore D): 85D

- HDT@0.45MPa (66psi): 60.0℃

Ideal for Studios and Individual Players.

For more detailed safety data sheets and additional information, please Click Link MSDS-Basic-En

[Instructions for use]

1.PREPARATION: Please shake well before use, if not be mixture by shaking enough, it may cause color variation and quality problems.

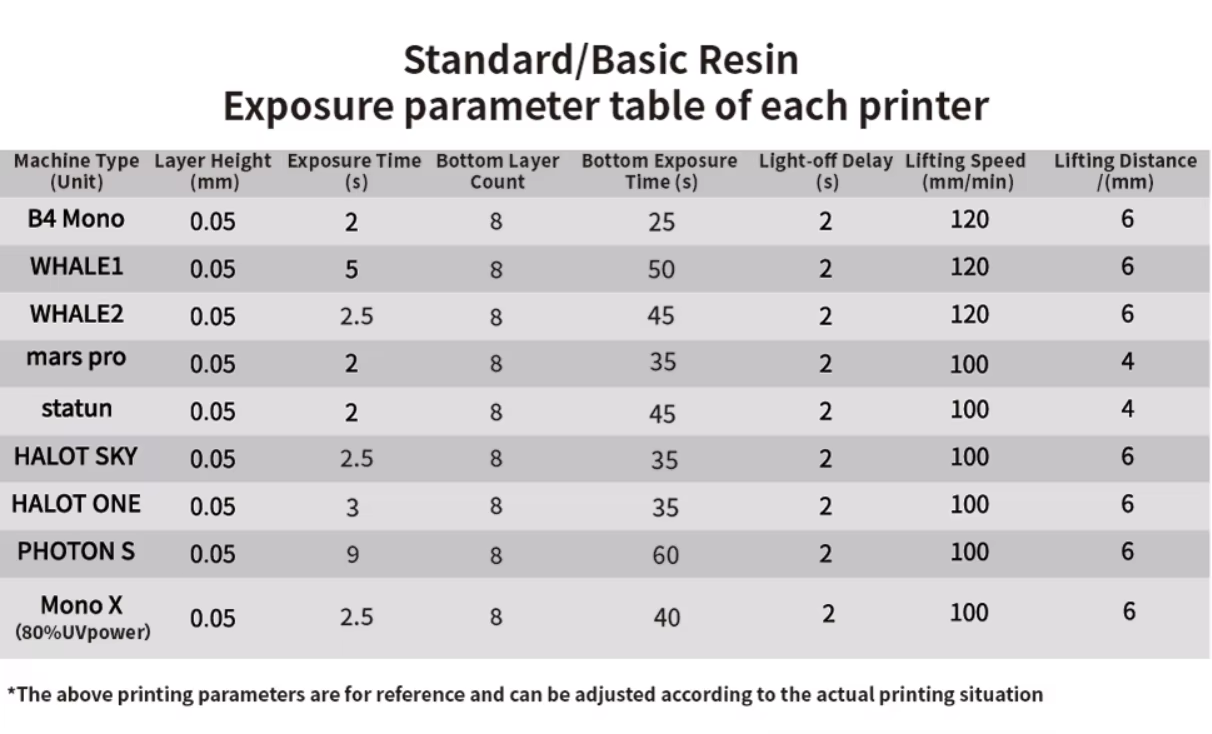

2.PRINTING: Pour the liquid resin into the 3D printer tank, follow the 3D printer instruction manual to print.

3.TAKE OFF: Use a scraper to remove the model after printing.

4.CLEANING: Immerse the model in alcohol or isopropanol with a concentration of more than 95%, and then ultrasonically clean it for 2 minutes to remove the uncured resin on the surface.

5.REMOVE THE SUPPORT: Use the scissors to remove the support if necessary.

6.Clean: clean the model with clean compressed air to ensure no alcohol and impurity residues.

7.Post-curing: post-curing treatment when placed in a UV curing box (refer to the TDS of the corresponding material for the post-curing process).

[Precautions]

1.lt is suitable for 405nm light source equipment.

2.This is the material of acrylic liquid with a slight odor. Please avoid direct contact with people. Please wear protective gloves, protective glasses, protective masks and protective clothing when using it.

3.Do not edible, if accidentally swallowed, rinse your mouth, and do not induce vomiting; if you feel unwell, please call the doctor immediately

4.The material requires proper printing parameters to achieve the best results.

5.The original packaging is harmful to the environment; the remaining liquid material waste cannot be discarded and should be treated as chemical products or treated as solid waste after fully solidified.

6.Please make sure to use it under the recommended environmental conditions. Humidity, low temperature, or high temperature printing environment may cause the quality of printed parts to decrease or even print failure.

[Production Date] See packaging label

[Expiry date] 24 months if the bottle sealed

[Storage Precautions]

Keep away from light, dry and ventilated environment, sealed and stored at room temperature.

[Packing]

The material uses PE bottles and paper packaging.

Bob –

I’m absolutely thrilled with my new resin 3D printer! The level of detail and precision it delivers is simply incredible—every print comes out crisp, smooth, and professional-looking. The setup was straightforward, and the interface is user-friendly, even for someone like me who’s relatively new to 3D printing.

I’m especially impressed with how quickly it prints without compromising quality. The resin curing process is efficient, and cleaning up is surprisingly easy once you get the hang of it. It’s perfect for intricate models like miniatures or prototypes. I can’t imagine going back to my FDM printer after seeing the results this machine produces. Highly recommend to anyone looking for a reliable, high-quality resin printer