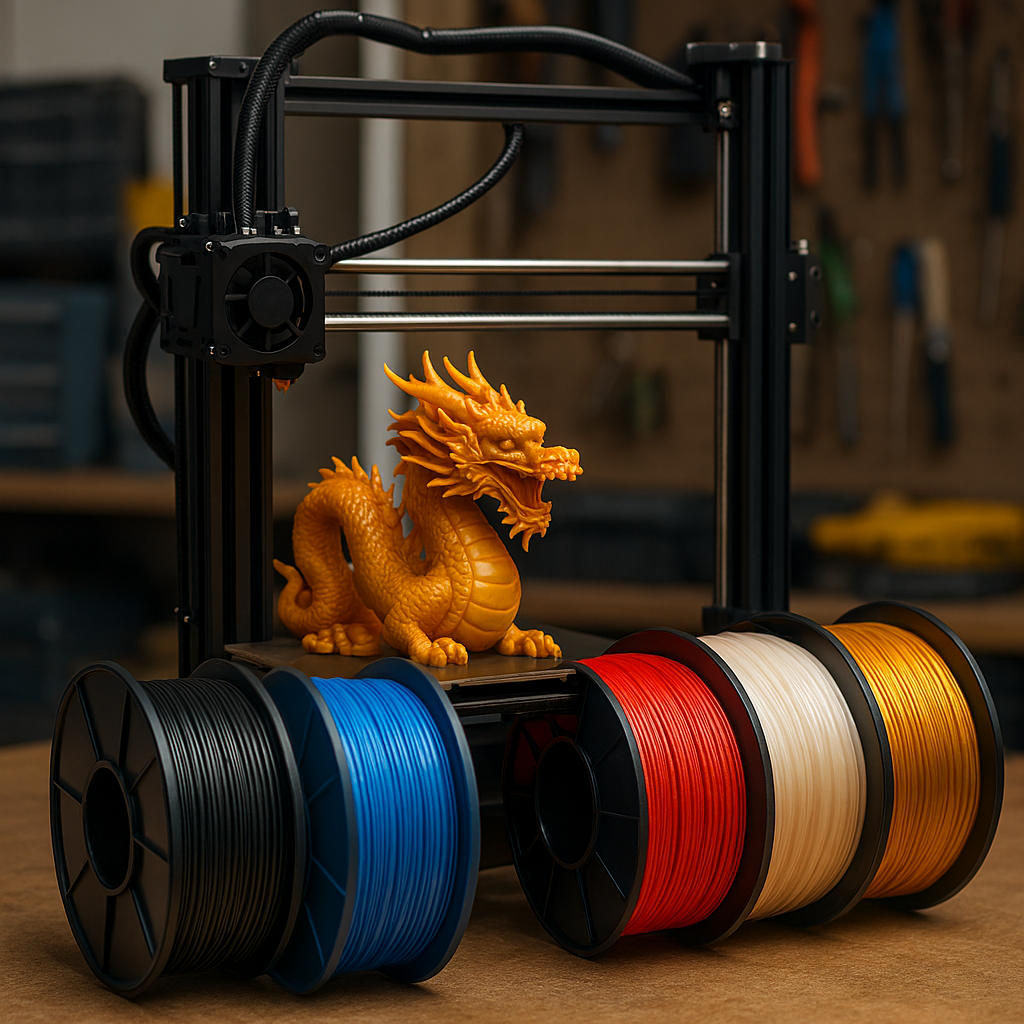

Filament (FDM Printing)

- Material: Usually thermoplastics like PLA, ABS, or PETG, which come in spools of solid, string-like material.

- Process: Filament printers (FDM—Fused Deposition Modeling) heat the filament and deposit it layer by layer to build the object.

- Strengths:

- Affordable and widely available.

- Great for larger models or functional parts due to their durability.

- Easier to handle and requires minimal post-processing.

- Limitations:

- Surface finish is often less smooth—layer lines are visible.

- Less suited for highly detailed or intricate designs.

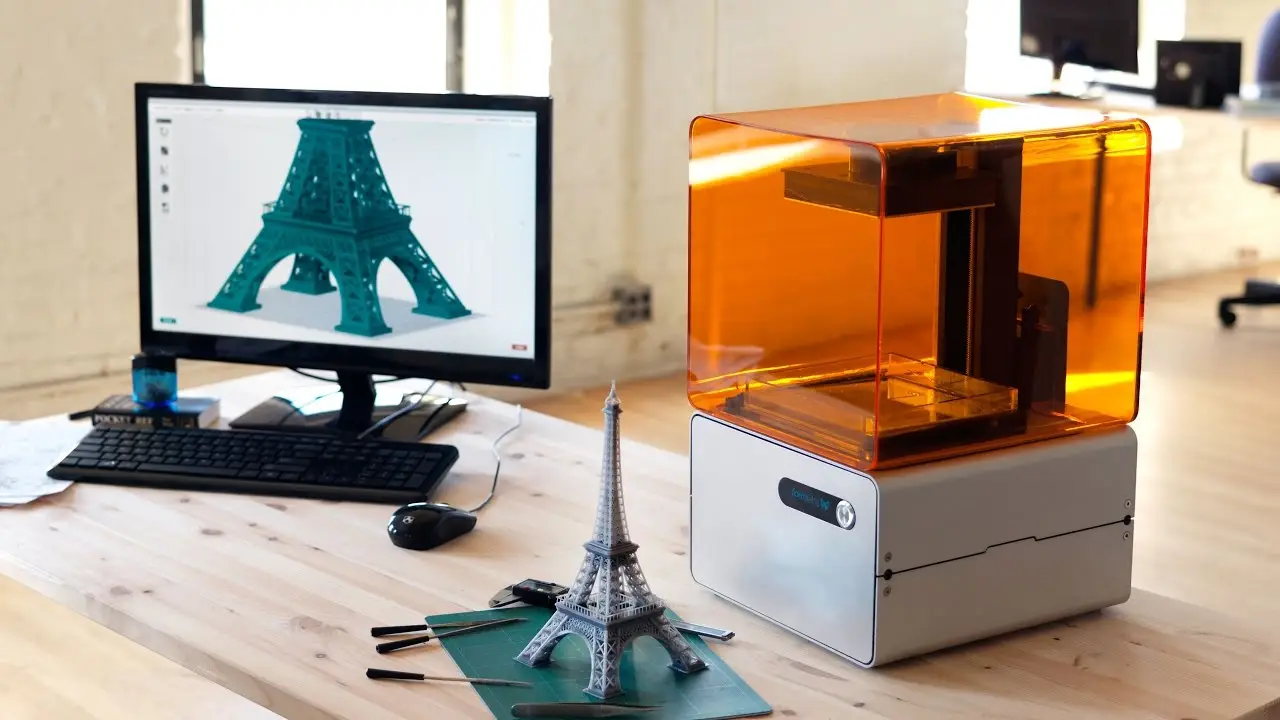

Resin (SLA/DLP Printing)

- Material: Liquid photopolymer resin, which solidifies when exposed to UV light.

- Process: Resin printers (SLA—Stereolithography or DLP—Digital Light Processing) use UV light or lasers to cure the resin layer by layer.

- Strengths:

- Superior detail and precision—ideal for miniatures, jewelry, or complex designs.

- Produces smooth surfaces with minimal visible layers.

- Limitations:

- More expensive than filament.

- Requires additional steps for cleaning and curing the prints (post-processing).

- Handling liquid resin can be messier and requires safety precautions.

There are 5 comments

I found this article really useful and engaging.

The site always provides high-quality and valuable content.

My web-site … astrohvarna.

Very good https://shorturl.at/2breu

Very good https://lc.cx/xjXBQT

Good https://is.gd/N1ikS2

Very good https://shorturl.fm/bODKa