Description

Enhance your 3D printing projects with our ABS Carbon Fiber Filament

This advanced filament combines the strength and durability of ABS (Acrylonitrile Butadiene Styrene) with the rigidity and lightweight properties of carbon fiber.

ABS-CF (Acrylonitrile Butadiene Styrene-Carbon Fiber) seamlessly blends the advantages of carbon fiber filament with the favorable mechanical characteristics and

user-friendliness of ABS 3D printing material. The outcome is an exceptional engineering thermoplastic, renowned for its unmatched strength and rigidity, ideally suited for factory floor tooling applications.

You can significantly slash lead times by choosing ABS-CF for 3D printing your tooling instead of traditional machining.

Depending on the specific application, the carbon-reinforced ABS can even serve as a substitute for metal, offering lighter and more ergonomic tooling solutions. Moreover, when combined with soluble support, ABS-CF10 allows for intricate geometries that were previously unattainable through machining processes. Embrace the power of ABS-CF and unlock the potential for innovation and efficiency in your tooling production.

ABS-CF (Acrylonitrile Butadiene Styrene-Carbon Fiber) seamlessly blends the advantages of carbon fiber filament with the favorable mechanical characteristics and

user-friendliness of ABS 3D printing material. The outcome is an exceptional engineering thermoplastic, renowned for its unmatched strength and rigidity, ideally suited for factory floor tooling applications.

You can significantly slash lead times by choosing ABS-CF for 3D printing your tooling instead of traditional machining.

Depending on the specific application, the carbon-reinforced ABS can even serve as a substitute for metal, offering lighter and more ergonomic tooling solutions. Moreover, when combined with soluble support, ABS-CF10 allows for intricate geometries that were previously unattainable through machining processes. Embrace the power of ABS-CF and unlock the potential for innovation and efficiency in your tooling production.

Features Application:

- Impact modified

- High strength

- Low warpage

- Low water uptake

Application:

- Cultural and creative

- Toys

- Gifts

- Industrial

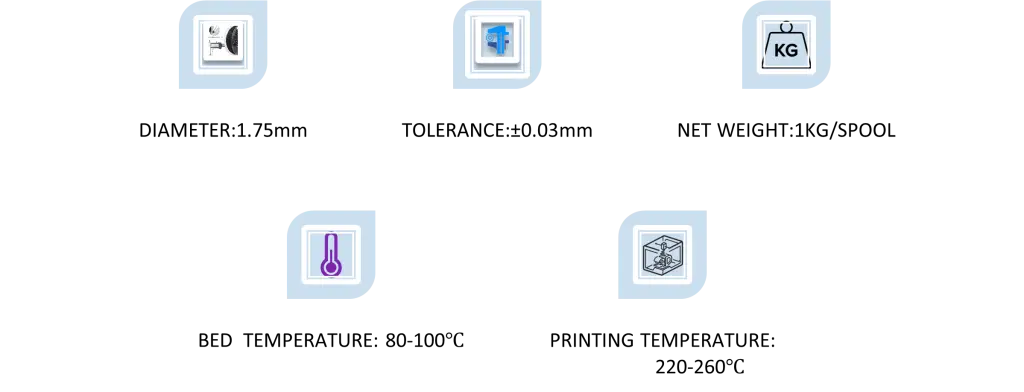

Product Specifications:

Technical Specifications:

- Tensile Strength(XY) 35 MPa/ ISO/ 527 50mm/min

- Tensile Strength(XZ) 40 MPa/ ISO 527/ 50mm/min

- Tensile Strength(ZX) 16 MPa/ ISO 527 /50mm/min

- Elongation at Break(XY) 2.3 % /ISO 527 /50mm/min

- Elongation at Break(XZ) 5.3 % /ISO 527 /50mm/min

- Elongation at Break(ZX): 1.2 %/ ISO 527 /50mm/min

- Flexural Strength(XY): 61 MPa/ ISO 178/ 5mm/min

- Flexural Strength(XZ): 65 MPa/ ISO 178 /5mm/min

- Flexural Strength(ZX): 24 MPa/ ISO 178 5mm/min

- Flexural Modulus(XY): 3071 MPa/ ISO 178/ 5mm/min

- Flexural Modulus(XZ): 2900 MPa/ ISO 178/ 5mm/min

- Flexural Modulus(ZX): 1135 MPa/ ISO 178 /5mm/min

- Unnotched Izod Impact Strength(XY): 18 KJ/m2 ISO 180@ 23℃

- Unnotched Izod Impact Strength(XZ): 11 KJ/m2 ISO 180 @23℃

- Unnotched Izod Impact Strength(ZX): 4.8 KJ/m2 ISO 180 @23℃

- Heat Deflection Temperature: 91 ℃ /ISO 75 120℃/h,0.45MPa

Reviews

There are no reviews yet.